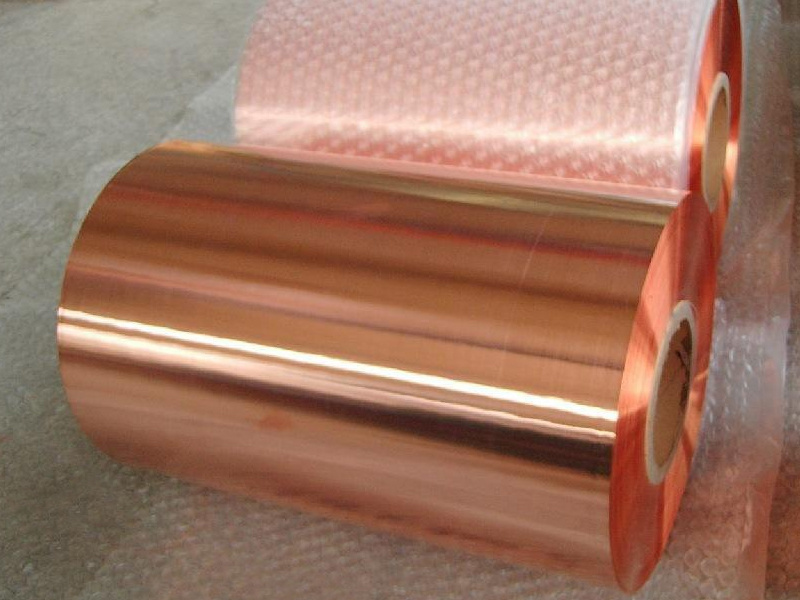

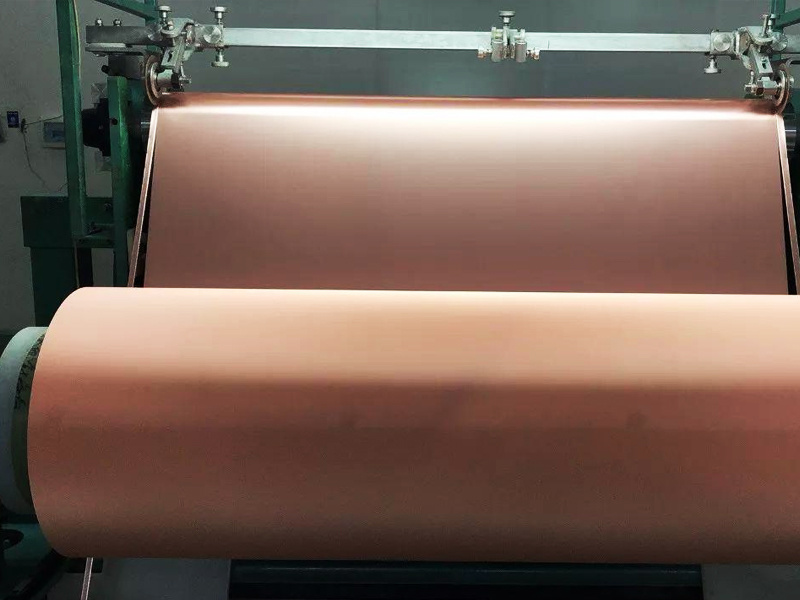

Electrolytic copper foil

Category:

Keywords:

Product Description

- 产品描述

-

Electrolytic copper foil (Electrode Posited copper) is made by first dissolving copper to create a solution, then using specialized electrolytic equipment to electrodeposit copper sulfate electrolyte under direct current to create the original foil. Then, according to requirements, a series of surface treatments are performed on the original foil, including surface treatment, heat-resistant layer treatment, and oxidation prevention treatment. Electrolytic copper foil differs from rolled copper foil in that the crystal morphology on both sides of the electrolytic copper foil is different. The side in close contact with the cathode roller is smoother and is called the bright side; the other side exhibits a crystal structure with an uneven shape, which is rougher and is called the matte side. The surface treatment of electrolytic copper foil and rolled copper foil also differs. Because electrolytic copper foil has a columnar crystal structure, its strength and toughness are inferior to rolled copper foil, so electrolytic copper foil is mostly used in the production of rigid copper-clad laminates, which are then made into rigid printed circuit boards. The main technical requirements for electrolytic copper foil (including those after roughening treatment) include thickness, standard quality, appearance, tensile strength, peel strength, high-temperature oxidation resistance, and the mass resistivity of the copper foil. In addition to the above seven main performance requirements, manufacturers in some countries and regions have other performance requirements, such as elongation, bending resistance, hardness, elastic modulus, high-temperature elongation, surface roughness, etchability, solderability, UV ink adhesion, and the hue of the copper foil.

With the miniaturization and sophistication of electronic products, and the higher requirements for the cruising range and safety performance of power in new energy vehicles, lithium-ion batteries are also developing towards higher capacity, higher density, and higher speed, and the requirements for battery materials are also increasing. High-performance lithium battery copper foil is emerging, and the overall technical performance is improving, including but not limited to the appearance quality, physical properties, stability, and uniformity of the copper foil, which are closely related to battery performance.

From the perspective of the copper foil industry chain, the industry chain is composed of upstream raw materials, midstream copper foil manufacturing, and downstream application fields. The upstream raw materials are mainly copper mining and smelting industries; the midstream is copper foil manufacturing and production, with two main products: rolled copper foil and electrolytic copper foil. The market share of rolled copper foil is mainly concentrated in Japanese and American companies, while the market share of electrolytic copper foil is more dispersed; the downstream application fields are mainly in electronics and information, lithium batteries, and building decoration.

Electrolytic copper foil is widely used in lithium batteries. In lithium battery cell materials, the cost of lithium battery copper foil accounts for 5%-8% of the total cost, and it is an important link in the supply chain layout of power battery companies; it is both a carrier for negative electrode active materials and a negative electrode electron collector and conductor, whose main function is to collect the current generated by the battery active material to produce a larger output current. Due to the good conductivity and machinability, relatively soft texture, mature manufacturing technology, and prominent cost advantages of lithium battery copper foil, it has become the preferred choice for lithium-ion battery negative electrode current collectors, and the possibility of being replaced is relatively low.

Leave a message

We attach great importance to your opinions and inquiries. If you have any questions about our products and services, please fill out the following form, and we will contact you as soon as possible.