Rolled copper foil

Category:

Keywords:

Product Description

- 产品描述

-

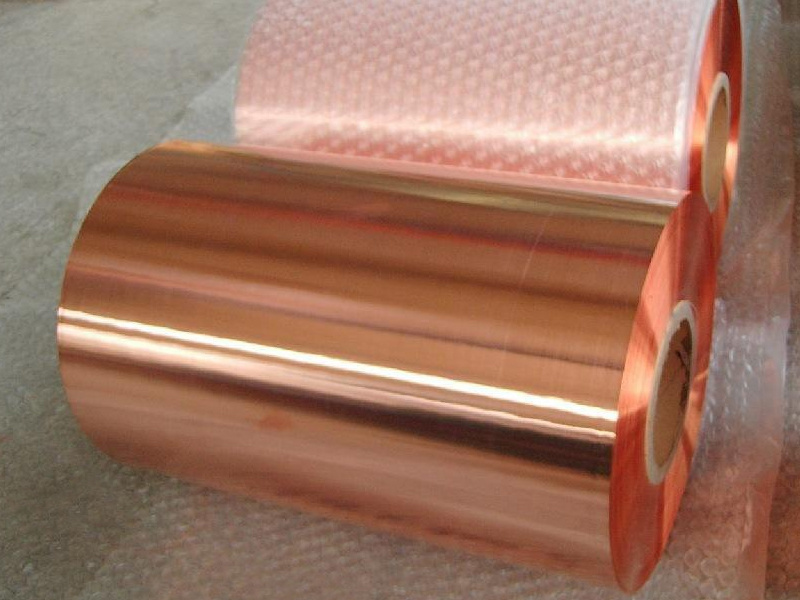

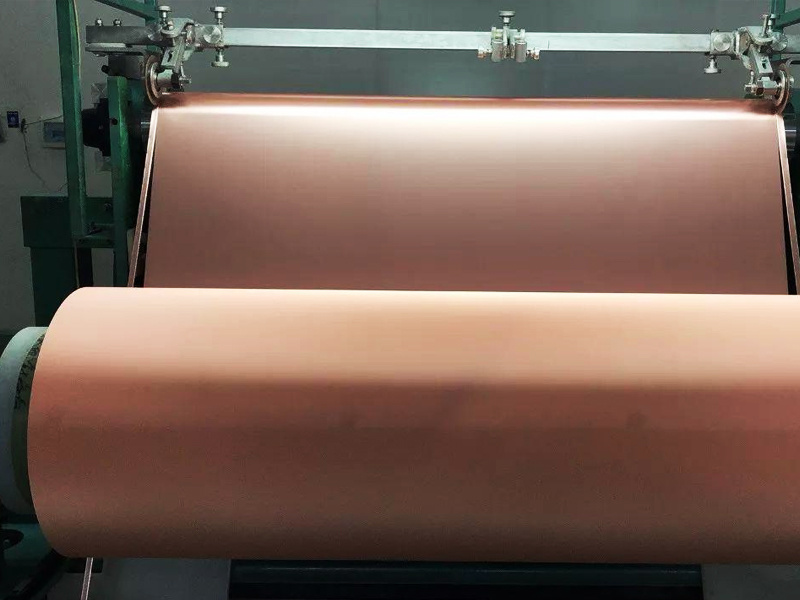

Rolled copper foil is a high-precision, ultra-thin, high-density deep-processed copper product with unique advantages of high strength, high conductivity, high flexibility, and low roughness. It is widely used in electronics, 5G, integrated circuits, aerospace, and other fields.

According to different manufacturing methods, copper foil can be divided into two categories: rolled copper foil and electrolytic copper foil.

I. Rolled Copper Foil

Rolled copper foil is made by repeatedly rolling copper plates multiple times to create the original foil (also called raw foil), which is then roughened as needed. Due to limitations in the processing technology of rolled copper foil, its width is difficult to meet the requirements of rigid copper-clad laminates, so rolled copper foil is rarely used in rigid copper-clad laminates. Because rolled copper foil has greater fold resistance and elasticity than electrolytic copper foil, it is suitable for flexible copper-clad laminates. Its copper purity (99.9%) is higher than that of electrolytic copper foil (99.8%), and its surface is smoother than that of electrolytic copper foil, which is beneficial for the rapid transmission of electrical signals. Therefore, in recent years, foreign countries have used rolled copper foil as the base material for high-frequency, high-speed signal transmission and fine-line printed circuit boards. Its use as a base material for printed circuit boards in audio equipment can also improve sound quality. It is also used in "metal core boards" designed to reduce the thermal expansion coefficient (TCE) of fine-line, multilayer printed circuit boards. In recent years, Japan has also launched new types of rolled copper foil, such as high-toughness rolled copper foil, a type of rolled copper foil with low-temperature crystallization characteristics. Due to its high bending resistance, it is suitable for flexible boards. Another type is oxygen-free rolled copper foil, which is characterized by an oxygen content of only 0.001%, high tensile strength, and is suitable for printed circuit boards in TAB applications requiring high lead strength, as well as printed circuit boards in audio equipment.

Leave a message

We attach great importance to your opinions and inquiries. If you have any questions about our products and services, please fill out the following form, and we will contact you as soon as possible.